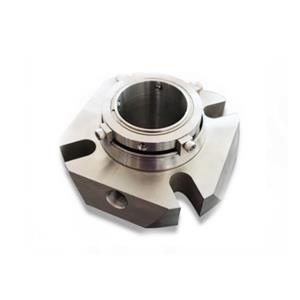

MS Magnetic Rolling Bearing Lubrication Oil Seal For Rotary Equipments

Brand GS

Product origin China

Supply capacity 10000sets

■MS Magnetic Oil Seals

Magnetic seal MARKETS SERVED

Pulp and Paper

Petrochemical

Oil Refining

Upstream and Downstream Oil and Gas

Offshore

Mining

Manufacturing

Food Processing

Pharmaceuticals

Magnetic oil seal designed for rolling bearing lubrication oil seals of all rotary equipments

1.Magnetic oil seal application fields

Designed for rolling bearing lubrication oil seals of all rotary equipments.

2.Operating Parameters

Temperature: to +150°C(+302°F)

Pressure: to 3bar

Speed: to 50m/s

Magnetic oil seal for high temperature

100% POSITIVE SEAL

MS bearing isolators offer all metallic primary construction and are both ANSI, API 610 approved.

MS magnetic oil seals outperform both lip and labyrinth seals and offer a range of benefits.

100% positive seal bearing protection with or without shaft rotation

Zero shaft wear

Bi-directional seal

Nickel-plated neodymium magnets resist corrosion

All materials rated to 400°F

No exposed moving parts

Self-aligning faces

Increases equipment MTBF

Prevents lubrication loss and eliminates contamination (solids, liquids and steam)

Reduces heat generation and maximizes seal life

Isolates magnets from lubricant

Handles low AND high speed applications

■Structure Features

Magnetic mechnical floatation design

Adopt permanent magnet materials as components

Contaminants are fully isolated

No wear of rotating shaft

Fit for high temperature and pressure

Increase bearing using life

Possibility to install without necessity to change equipment

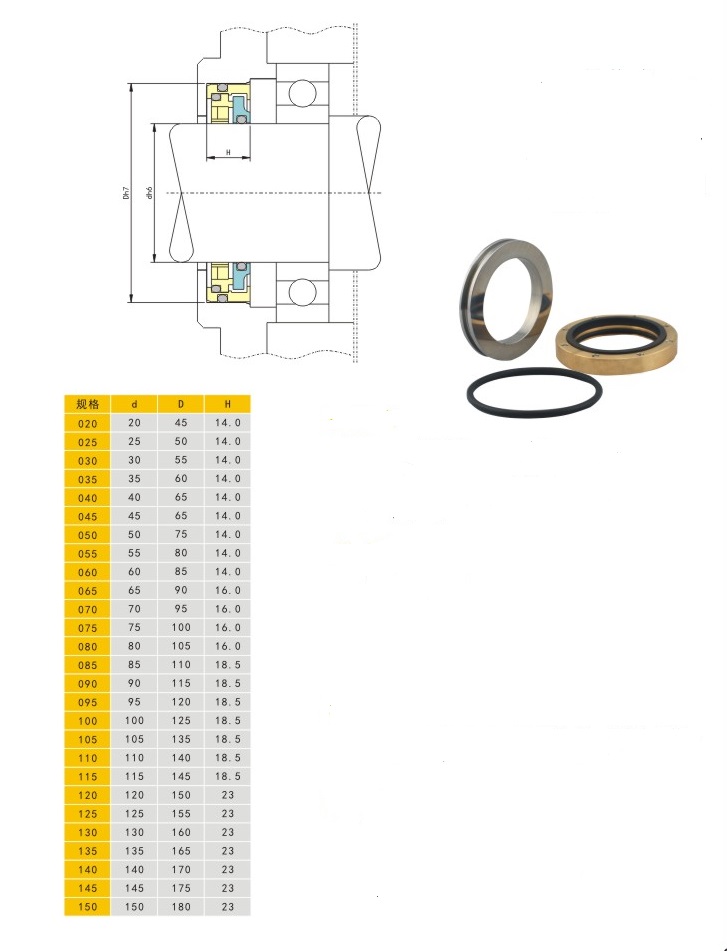

■Precision Requirements

Radial runout:Maximum 0.5mm

Axial runout: Maximum 0.35mm

Shaft torlerance:Maximum ±0.05mm, recommend ±0.025mm

Shaft roughness:Maximum Ra1.6

Tolerance of stationary face:H7

Liaoning Grand trade Co., Ltd is a high-tech and exporting enterprise integrating product research, design, manufacturing, sales and service.

Our main products:Mechanical seal(spring mechanical sea, welded metal bellow seal,water pump seal,elastomer bellow seal,high speed seal,cartridge seal),Seal supply system ,Vacuum welded metal bellows,Magnetic oil seal,seal parts of mechanical seals(silicon carbide,tungsten carbide,carbon graphite,elastomer o ring),bronze bearing and seal spare parts etc. The products are applied in many fields such as petroleum, chemical industry, electric power manufacturing, refrigeration, ship building, aviation, aerospace and so on.We have established long-time and stable cooperation relationship with many European ,American and Asian customers.

Packing:Standard & Strong Packing by air / sea

Poly bag + Box + Carton + Pallet

Can be with our brand packing, or OEM with your brand and design

Delivery: By Sea, By Air, By Train, By Truck, By Express company as your needs

Terms:EXW, FOB, CFR, CIF, DDU , if you need Door to Door please contact us