What is the replacement procedure for high temperature bellow seal

High temperature bellow seal is very important for chemical pumps, hot water pipeline pumps and oil pumps. The installation of high temperature bellow seal can make water pumps run without leakage, which greatly improves the working environment of water pump managers and prolongs the service life of water pumps .

The following is a detailed explanation of the installation steps of welded metal bellow mechanical seal:

(1) Prepare the workbench (ground) and disassembly tools for placing the pump parts, and do not place them indiscriminately to avoid damaging the pump parts.

(2) Confirm that the motor is in the maintenance state before disassembly; unscrew the oil filling screw plug, and use a straw to suck out the lubricating oil in the sealing seat cavity.

(3) Disassemble the split coupling: first unscrew the fixed hexagon socket head screw of the coupling, and then gently pull half of the coupling off the shaft slowly (be careful not to fall off). Use a ring wrench to unscrew the pump shaft hanging bolts and stoppers, let the impeller slowly sink to the pump body, remove the other half of the coupling, and take off the pump shaft retaining ring.

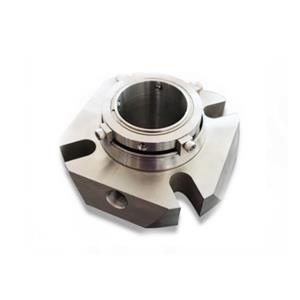

(4) Disassemble the seal seat: Unscrew the seal seat, tighten the nut, gently remove the seal seat of the balanced single bellow seal (note: do not break the rubber oil seal on the seat) and clean it.

(5) Disassemble and clean the bearing seat: first move the bearing seat lightly, then use the dismounting bolts to lift the bearing seat, and lift it up along the pump shaft to remove it; clean the bearing and seat with jet fuel, dry and dry before installing Apply a little No. 20 mechanical oil for lubrication and protection.

(6)Remove the high temperature welded metal bellow seal: grab the seal spring and lift it up along the pump shaft to remove it.

(7) Mechanical seal assembly: apply a layer of clean No. 20 lubricating oil on the mirror surfaces of the dynamic and static rings; apply lubricating oil to the guide bearing seat, first gently position the static ring into the guide bearing seat; then install it on the pump shaft Apply lubricating oil, gently install the moving ring part of the mechanical seal on the pump shaft, and push the sealing ring lightly by hand to expand and contract freely.

(8) Install the seal seat: first install the rubber oil seal on the seal seat of the welded metal bellow seal with drive lugs, then put the seal seat into the pump cover and press it on the bearing seat, and tighten the nut.

(9) Coupling installation: first install a retaining ring on the motor shaft head, install half of the coupling, then install a block on the pump shaft end and the coupling groove and tighten the bolts with a ring wrench (; then install another The hex socket head screws on half of the coupling must be tightened.

(10) Test run according to the main points of use to check whether the replacement of the mechanical seal is correct and whether the pump unit is operating normally.