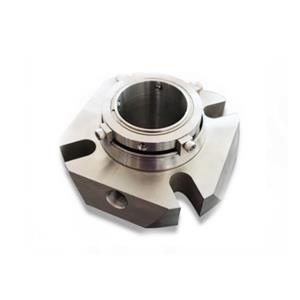

sic and ssic

Reaction Bonded Silicon Carbide(SiC)

Reaction Bonded sic is sintered by adding the free silicon (content is less than 12%) into the reaction sintering sub-micron Silicon carbide powder in 1500 ℃ vacuum sintering furnace. Under high temperature, the free silicon reaction enhances its lubrication performance and reduces its friction coefficient and therefore strengthens the characteristics of wear resistance and plasticity. The maximum overall sealing ring can be as big as 800mm. So it is widely used in the bearing, petroleum, chemical, motors, ships and pump valve industries.

Features

The mirror image of Reaction bonded

silicon carbide materials shows that

under 200 ×optical microscope,

crystals and free silicon (no more than

12%) presents uniform distribution

and size after the chemical processing

of the material section.

Sintered Silicon Carbide (SSiC)

Sintered Silicone carbide is sintered of sub-micron silicon carbide powder in 2100℃ vacuum sintering furnace. Because its fine crystal structure single-phase is able to keep high strength at high temperature, ssic products with high purity and high density make it have very strong corrosion resistance. lts excellent finish properties make it Particularly suitable for application in mechanical seal face, valve, bearing, petroleum, chemical, aerospace, automotive industries.

Features

The mirror image of Sintered

Silicone carbide after corrosion

under in 200 X optical microscopy

shows the distribution of crystal

and size is uniform and the

biggest crystal is no more than

10μm.