- Mechanical Seal

- Welded Metal Bellow Mechanical Seal

- Rotary And Stationary Multiple Spring Mechanical Seal

- Cylinder And Conical Single Spring Mechanical Seal

- Wave Spring Mechanical Seal

- Elastomer Rubber Bellow Shaft Seal

- Teflon Bellow Mechanical Seals

- Dry Gas Seal For Pump

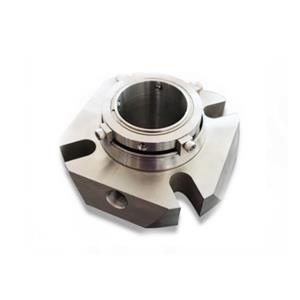

- Standard Cartridge Mechanical Seals

- Single And Double Agitator Mechanical Seals

- Double Faces Spring And Bellow Mechanical Seal

- Spring And Metal Bellow Seal For High Speed Gear Pump

- Stationary Cartridghe Seal For Slurry Pump

- Automotive Water Pump Seals

- Cartridge Mechanical Seal For Grundfos Pumps

Introduction of welded metal bellows

Welded metal bellow is a flexible, convoluted metal component that is made by welding multiple thin metal sheets. The convoluted shape of the bellow allows it to expand and contract with changes in pressure, temperature, or movement, making it ideal for use in applications where flexibility and durability are essential.

These metal bellows are commonly used in a variety of industries, including aerospace, automotive, medical, and industrial manufacturing. They can be used to isolate vibrations, compensate for thermal expansion, and absorb axial or lateral movements in piping, vacuum systems, and other applications.

Welded metal bellows are typically made from high-performance alloys such as stainless steel, Inconel, Hastelloy,or titanium, depending on the specific requirements of the application. The welding process used to manufacture these bellows creates a hermetic seal that prevents gas or liquid from leaking out of the system.

Overall, welded metal bellows are a critical component in many mechanical systems, providing reliable and flexible solutions to complex problems.