Five small methods to solve the problem of mechanical seal leakage

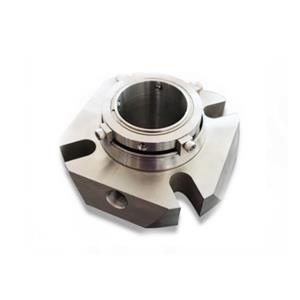

The characteristic of mechanical sealis that it can be used for all kinds of equipment, especially for equipment such as reaction kettle and pump, because the sealing requirement of such equipment is very high, and it can't enter impurities, so it is used more. The problem of water leakage is really worrying. The sealing effect of the seal becomes worse due to water leakage. This is something that many people taboo. Here are five tips to help you easily solve the seal leakage problem:

Reason:

1. The equipment is too tight. Check the dynamic ring plane of wave spring seal, if there is a serious scorch appearance, plane blackening and deep marks, pump mechanical seal rubber hardens and loses elasticity, this appearance is due to the tight equipment.

2. The equipment is too loose. Inspection machine sealing dynamic, static ring plane, its surface has a very thin layer of scale, can be erased, the surface is basically no wear, which is composed of the loss of spring elasticity and poor equipment, or the axial movement of the motor.

3. The water quality is poor. Due to the poor water quality of containerized wave spring seal, rich in small particles and high content of hydrochloride in the medium, grooves and ring grooves occur on the plane or pull surface of the abrasive wear machine seal.

4. Dry grinding damage is caused by water shortage operation. This appearance is more common in the negative pressure at the entrance of the bottom valve type equipment method, there is air in the inlet pipe, there is air in the pump cavity, after the pump is turned on, the friction of mechanical seal occurs high temperature during high-speed operation, can not get cooling, check the machine seal, the spring tension is normal, the contact surface is scorched and blackened, and the rubber hardens and cracks.

5. Cavitation. Cavitation mainly occurs in hot water pumps. Because the medium is hot water and the water temperature is too high, the steam in the pipe enters the high part of the pump cavity, and this part of the vapor can not be cleaned, and then constitute a water shortage operation, machine seal dry grinding failure, cavitation installed automatic exhaust valve, switch.

Solution:

1. Treatment method: Adjust the height of the equipment. After the impeller is installed, use a screwdriver to pull the spring. The spring has a strong tension, and it will reset after loosening. There is only a moving distance of 2 to 4 mm.

2. Adjust the height of wave spring mechanical seal and return spring.

3. Improve the water pressure or medium, and switch the seal.

4. Exhaust the air in the channel and the pump cavity, and replace the mechanical seal.

5. Do not use hot water as much as possible.

The water leakage of the wave spring unbalanced seal is not a trivial matter, and it may cause failure if it is not done well. Therefore, we must find out the cause in time when encountering this problem. Don't just throw it around. There is also the use of mechanical seals under appropriate conditions. And keep the water clean.